HISTORIC MALDON DISTRICT: Down on the Farm – memories of Little Totham in 1952

By The Editor 12th Sep 2021

Retired schoolteacher Ronald Sampson has sent in more of his fascinating memories of his youth spent in Maldon during the War and the immediate years after.

'I spent most of the eight weeks summer vacation on a friend's farm in Little Totham. I was not paid, but given board and lodging. It was a small arable and dairy farm worked by the owner and his son.

Dairy farming meant being up very early in the morning, and fetching the cattle from the field and into the milking parlour. Each cow seemed to know which stall to enter, and the milking machines were put on the udders. While I was strolling back and forth to ensure all was operating properly and going into the stall to see they had enough to eat, one cow was very cheeky to me. She always used to gently squash me against the wall, like a good morning hug. She meant no harm, as Molly and I were friends, as can well be seen from the photo.

The removal of the machines not the end, as the udders had to be 'stripped' to ensure all the milk was out. The cows were then returned to their pasture, and the pails of milk carefully decanted into sixteen-gallon churns. These had to be manhandled to the farm entrance and lifted up to a three foot high wooden platform, so the collecting driver could slide them onto his trailer – no tankers in those days. Next job? To thoroughly clean the stalls and walkway after the non-house-trained animals, and then to breakfast.

The main occupation at that time of year before the harvest was hoeing in the small fields, and preparing the machinery for harvesting. This had four phases: reaping, stooking, threshing and storing. Being a rookie, I was not allowed to drive the tractor for reaping, but sat on an iron seat on the binder with a long stick to clear any hold ups.

The flails knocked the stalks down towards the cutters, and they were then tied up and shot out of the side. When the field was cut, it was covered in sheaves. These were manually picked up, and stood up in sixes which were called stooks, with the ears uppermost for drying.

As the weather was fine, it was soon time for threshing. The sheaves were pitchforked onto a waggon, which, when loaded was taken to where the threshing was to take place. The thresher was hired, and mainly operated by the firm's team. It was powered by a large steam engine, which operated it via a long fast-moving leather belt. Everyone kept quite clear of this!

The string around the sheaves was cut, and they were fed in one at a time, where they were jostled about to remove the seeds which were ejected into a container on the side. At the other end, the straw was carried up a spiked belt and tipped out.

If the haystack was to be there, the ramp could be lowered first, and gradually raised as the stack grew. If not, it was loaded onto a waggon and taken to where the stack was going to be made – all very labour intensive and hard work, with the only respite being when the seed was being bagged and a new container placed in position.

Many farmers then used to burn the stubble before ploughing, but this farmer didn't, as his buildings were nearby.

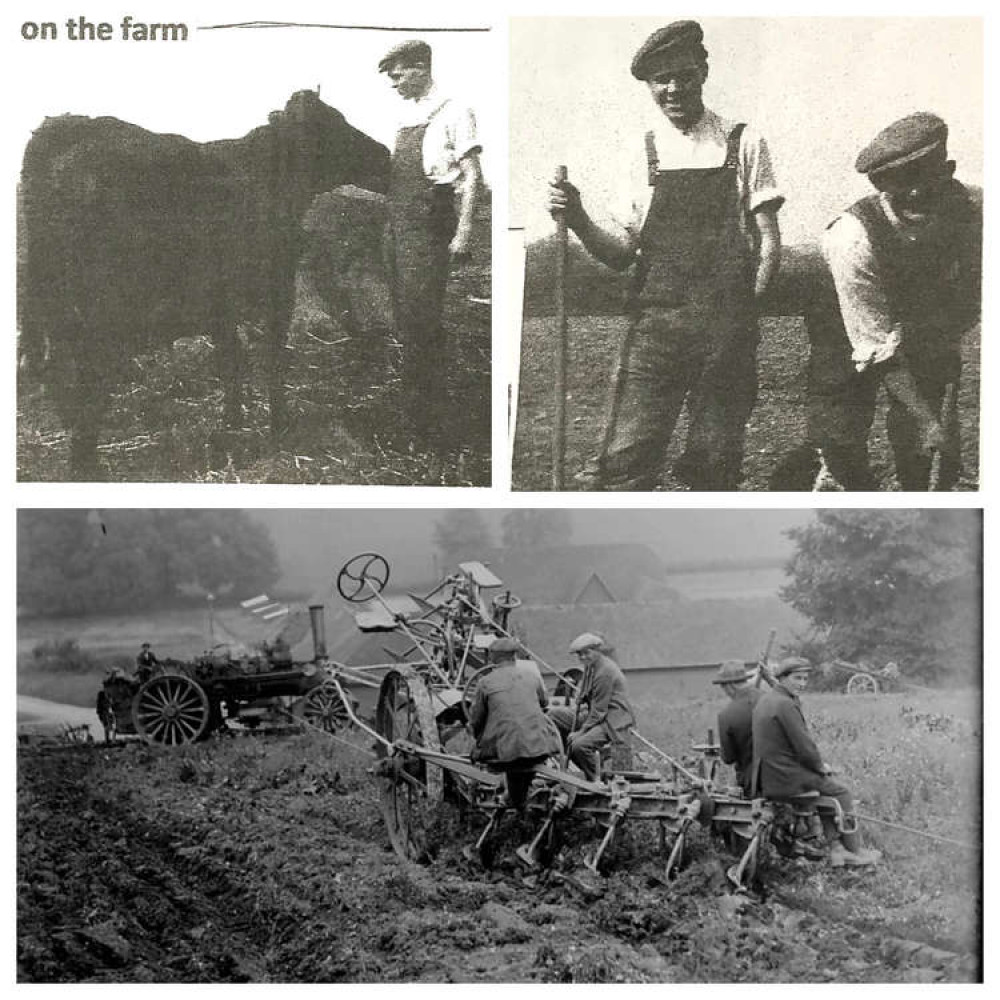

I left before ploughing began here, but observed a very unusual method on nearby very large farm. A large steam engine was placed on opposite sides of the field, and a complicated ploughshare was pulled back and forth on a continuous wire. This seemed to take six men to operate, and I couldn't help wondering if one man and a tractor (or even six men and six tractors) wouldn't have been quicker and cheaper!'

- If you have enjoyed this article you may want to support Ron in his bid to raise funds for the Dementia UK charity in memory of his beloved wife Sheila. To donate to Dementia UK you can visit the charity's website using the link here.

CHECK OUT OUR Jobs Section HERE!

burnhamanddengie vacancies updated hourly!

Click here to see more: burnhamanddengie jobs

Share: